A test fixture has a top surface with holes where test pin receptacles and guide pins may be inserted. At each test pin point, a pin receptacle is inserted. A spring-loaded test pin (or Pogopin) is then inserted into each receptacle so that it will make contact with desired test point on the PCBA. The PCBA is placed on top of the pins and then pressed down so that the pins make good contact with the test points.

The Macaos Integrated Test Jig includes a lower test fixture with pins and receptacles inserted. Fixture plates for the Box or Legacy jigs are supplied without pins or receptacles. For these jigs, you will need to acquire and insert appropriate pins and receptacles into the test fixture plate.

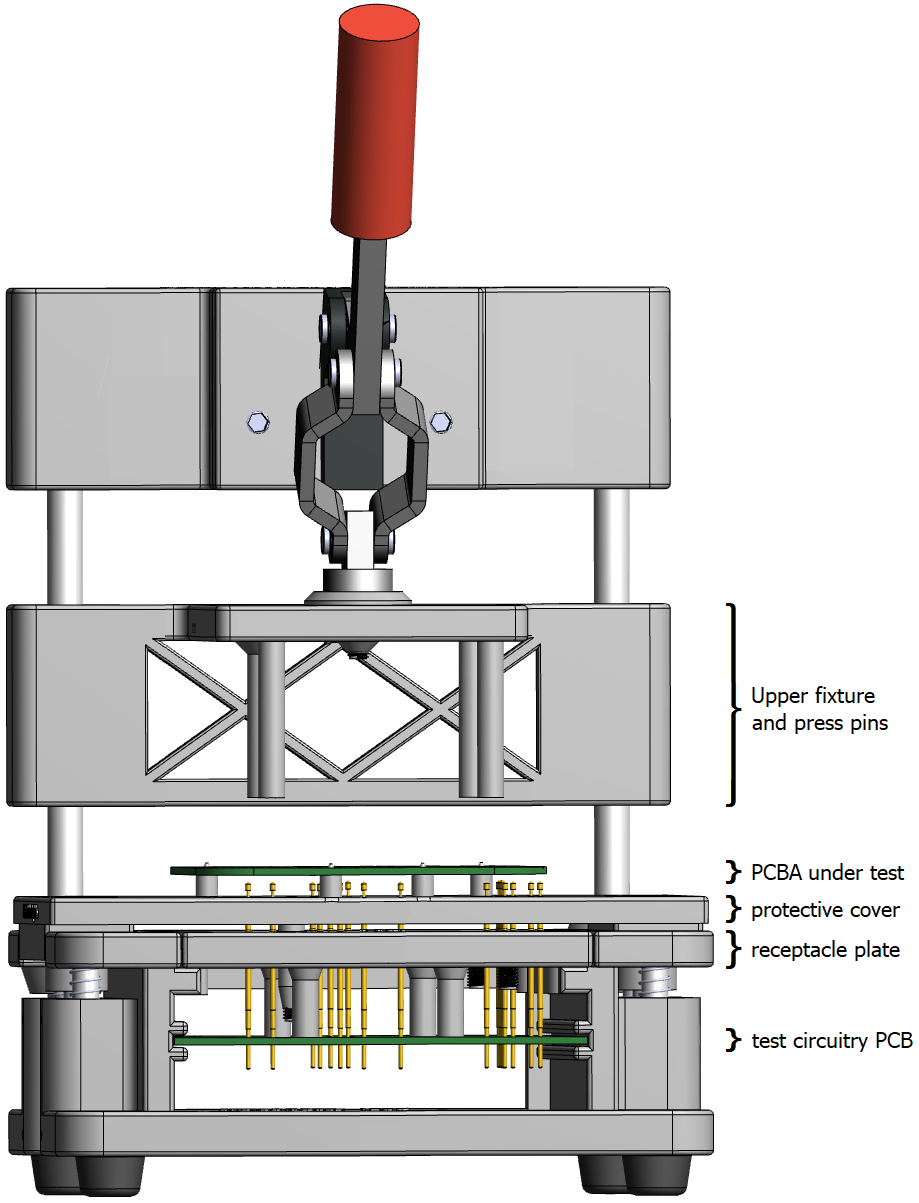

Ideally, all test points should be accessible to the lower test fixture. The Macaos Integrated Test Jig does not support test points on both sides. However, for the Box or Legacy jigs, a PCBA-specific upper fixture may be designed, if necessary.

Macaos Integrated Test Jig

Macaos Integrated Test Jig

The Macaos Integrated Test Jig incorporates an upper press fixture, a protective cover, a receptacle plate, and a test circuitry PCB. This is delivered fully assembled, with pins/receptacles installed.

To insure stability and compatibility, only P100/R100 and PL75/RL75 pins and receptacles are supported. When defining test points, the desired pin head style must be specified. It is also necessary to specify suitable locations for guide/support pins. (Press pins are placed at the guide/support pin locations.)

Use the Gerber button to generate a Gerber file of the test circuitry PCB outline and pin locations, for import to your CAD system. Connectors and indicators may be placed at the front and/or back edge of the PCB.

Note: The Integrated test jig does not support test points on both sides of the PCBA.

Macaos Box test jigs

With the Macaos Standard test jig, the lower fixture is a box, in which test circuitry may be installed as desired. The box height is always 91 mm, but its width and depth may be expanded as necessary. Connectors may be mounted in the sides or top of the box. This jig supports three fixture styles:

-

Lower fixture: The top surface of the box has holes for test pin receptacles and guide pins.

-

Lower w/ PCB fixture: The top surface of the box has a 240x140 mm opening, over which a PCB with test pin receptacles and guide pins is laid. We recommend a 3.2 mm thick PCB. Use the Gerber button to generate a Gerber file of the PCB outliine and pin locations for import to your CAD system.

-

Upper: An upper fixture has holes for test pin receptacles that will hold the test pins which make contact with the upper side of the PCB.

Legacy jigs

Legacy jigs are early versions of the Macaos test jig. They have a fixed box size and active area. The lower fixture rests on top of the jig box. These jigs support three fixture styles:

-

Lower – box: The lower fixture is a box where connectors may be mounted in the side walls. The top surface of the box has holes for test pin receptacles and guide pins.

-

Lower – flat: The fixture is a plate with holes for test pin receptacles and guide pins.

Alternatively, the fixture may be a PCB in which test pin receptacles and guide pins are installed. We recommend a 3.2 mm thick PCB. Use the Gerber button to generate a Gerber file of the PCB for import to your CAD system. -

Upper: An upper fixture has holes for test pin receptacles that will hold the test pins which make contact with the upper side of the PCB. For the 12/20 jig, two widths of upper fixtures are supported.

Test fixture protective cover

A box or legacy test fixture may be supplied with a protective cover. This is an additional plate (same material as the fixture) with holes drilled to allow all of the test pins to pass through it. Support pins hold the protective cover up, so that all of the test pins are “hidden” in the holes of the protective cover. When the test jig handle is pressed down, the protective cover is pushed down and the test pins make contact with the PCBA.