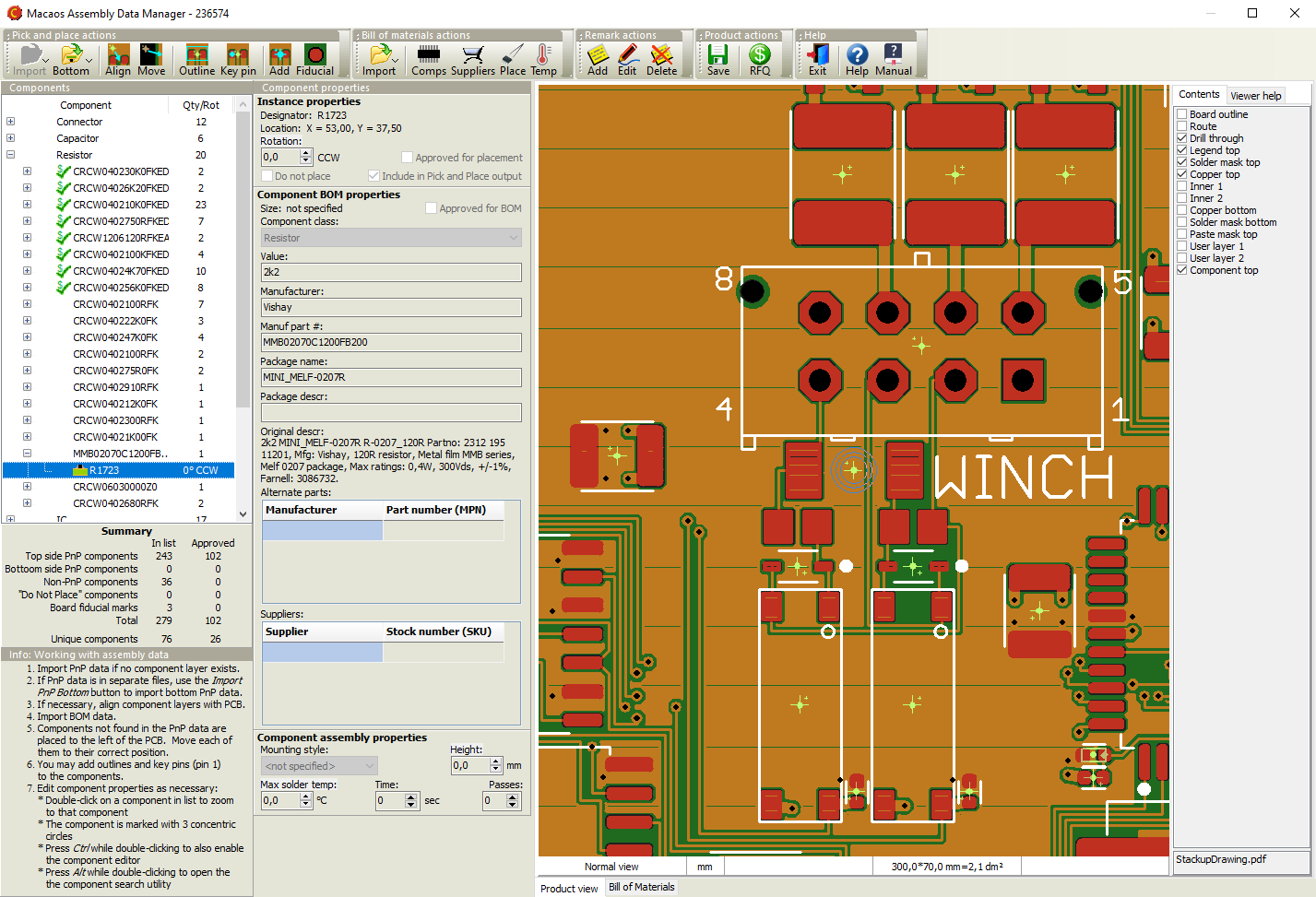

The Assembly Data Manager (ADM) is an integrated BOM Tool and Pick and Place Data Manager for PCBs. It provides an environment for managing and reviewing Pick and Place (PnP) and Bill of Materials (BOM) data.

An integrated, standards-based solution

The ADM helps dramatically reduce time and effort in preparing assembly data, by combining the following features in a single module:

- Graphic viewer with component editing functionality

- Structured component overview with properties editor

- Component search facility, powered by Octopart

- Component rotation, height and solder temperature editor

- Send RFQ for assembly to participating EMS providers (Basic version only)

- Component price estimator, powered by Octopart (EMS version only)

- Export PnP and BOM data (EMS version only)

The ADM makes use of the recently released X3 extensions1 to the Gerber Format which combine PnP, BOM and Assembly Drawing data into an integrated component layer of a PCB product. As CAD systems2 implement these extensions, a rapid and error-resistant path from designer to manufacturer may be achieved.

The component layer displays the location, rotation, size and key pin location of each component, together with properties such as manufacturer part number, supplier SKUs, height, max solder temperature, etc. The use of a standards-based structure for this information allows purchasers, suppliers, process line operators, etc. to automate their systems and thereby reduce costs.

1 Macaos actively participates in the development of these standards.

2 Some CAD systems, such as kicad, already support Gerber X3 output.

An efficient and straightforward workflow

An efficient and straightforward workflow

- Import PnP data. (This may already have been done when the PCB product was imported.) This should be done prior to importing BOM data.

- If necessary, align the PnP data with the PCB data.

- Import BOM data. (This may already have been done when the PCB product was imported.)

- If necessary, move new components to their correct position. BOM components are matched to PnP components by their designators. BOM components which are not found in the PnP data are placed to the left of the PCB. Each of these should be moved to its correct position on the PCB.

- Draw outlines and mark Key Pins. For assembly purposes, it is desirable to graphically display the size and orientation of each component. This information is typically not included in the imported PnP or BOM data, but it can easily be added by drawing outlines and marking key (1 or A1) pins.

- Check/edit the properties of each component. Ideally, a complete manufacturer part number should be specified for each component. If desired, alternate part numbers may be specified, and parts may also be marked as Equivalent or better. At the minimum, each component description should be unambiguous. The edit module includes an online component search function (powered by Octopart) to aid in quickly specifying unambiguous manufacturer part numbers.

- Save changes to the product and generate reports as desired.

Request a quotation for assembly

Once the BOM list is complete, Macaos Enterprise users can send an RFQ for assembly to participating EMS providers. This makes the PCB data and assembly data visible in the EMS provider's Macaos Enterprise so that they can prepare their quotation without you needing send data by unsecure means (such as e-mail).

Macaos Enterprise EMS version allows an EMS provider to track and review incoming RFQs. For more info about becoming an EMS provider listed in this module, click here.