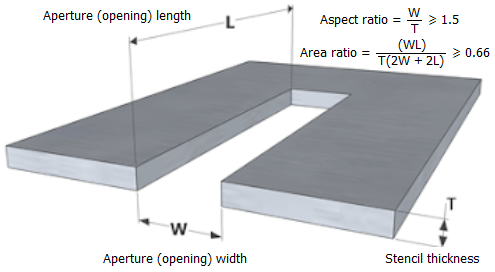

In order to achieve good solder paste release from a stencil aperture to the pad there are two ratios that matter:

- Aspect ratio: the relation between the width of narrowest aperture and the thickness of the stencil. This ratio should be at least 1.5.

- Area ratio: gives a more accurate and detailed indication of a stencil’s paste release performance. This is the ratio between the area of the aperture and the area of the hole walls. This ratio should be at least 0.66.

These ratios are calculated using the smallest apertures in the stencil.

If no stencil thickness has been selected, then a recommended maximum stencil thickness is displayed. Once a stencil thickness has been selected, then the aspect ratio and area ratio is displayed. In either case, click on the Show apertures button to highlight the apertures used in the calculation.