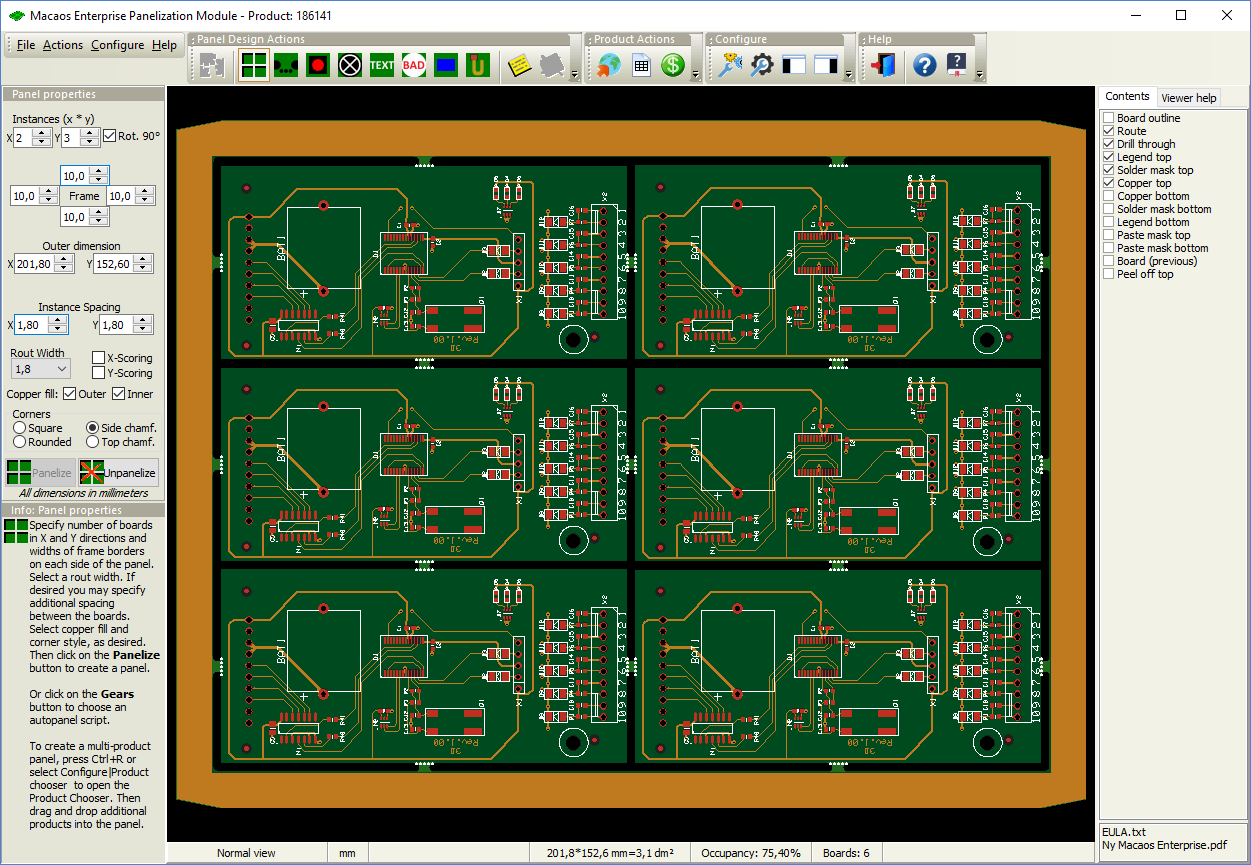

Macaos has developed an intuitive, yet flexible, rapid PCB panelizer tool.

Assembly arrays/panels

The Panelizer Module allows you to quickly step up a PCB board to an array (panel) suitable for assembly. The panel may be generated automatically from a script or you may specify panel parameters and add features to the panel frame as desired. Downloadable scripts from EMS providers may be used or modified to meet your own needs.

You can easily add features to the panel, such as:

- Break-off tabs: corner tabs or edge tabs with or without mousebite holes

- Fiducial marks: round, square or cross, placed relative to panel or board corners or centers

- Tooling holes or slots, placed relative to panel corners or center

- Break-off holes

- Bad marks

- Copper fill in frame and between boards

- Text

- Bar code, Code 128B or Datamatrix

- Annotation field

- Peel-off, glue or other assembly mask data

- Registration control coupon

- Impedance test coupon (IPC-2221B type Z)

Most of these features may be specified in a panel script, so that they are automatically added to any panel that you create using that script.

A WYSIWYG viewer shows your panel just as it will be interpreted by the manufacturer. A high-quality technical drawing of the panel in PDF format is automatically generated when the panel is saved.

Pick and place data (if included in the board product) is stepped together with the boards. Once the panel product is published, right-click on a Pick&Place layer to export pick and place data for the panel.

Multi-product panels

Panels that combine several different products are also supported. Start by selecting a single product in the product browser and open the panelization module. Then use the File|Open command to add an additional product to the panel. Be sure that the products are compatible with one another (i.e. same stackup, finish, mask colors).