Depanelizer module

Depanelizer module BruceDepanelization is the process of removing individual boards from a panel, after the boards have been populated with components. Traditionally, boards have been depanelized by breaking or cutting the the break-off tabs which hold the panel together. However, the mechanical forces (particularly bending) which can take place may weaken or damage the solder joints of fine-pitch SMT components near the board edges. This problem can be mitigated by using a milling machine to remove the break-off tabs.

The Depanelizer module allows you to easily and quickly accomplish the two specific tasks required for depanelization by milling machine:

-

Generate a milling program for removing the break-off tabs from a panel. A milling program contains the numerical instructions for operating a CNC milling machine which removes the break-off tabs from the panel.

-

Design a fixture for holding the panel frame and boards in place during the milling process. The depanelization fixture holds the boards in place, so that they do not move or otherwise get damaged during the milling process. Macaos has developed an inexpensive and reliable fixture style for this purpose. The fixture uses registration “pedestals” and vacuum suction to hold the boards in place as they are loosened from the panel, as well as a suction nozzle to remove dust from the milling process.

Generating a milling program

Generating a milling program Bruce-

Locate the product to depanelize. Select the product in the Macaos product browser and then click on the Depanel button to open the Depanelization module.

-

Locate the break-off tabs. Click on the Auto-tab button. This should automatically create a depanelization segment for each break-off tab in the panel. This operation looks for all gaps between slots in the panel that are less than specified Tab width. If necessary, you may need to adjust the tab width and try again. Note: Gaps that are smaller than 1.5 mm less than the specified tab width are ignored.

If tabs are placed at the corners of a rectangular board, they may be removed by drilling rather than by milling. The main advantage to drilled corner tab removal is improved stability during tab removal, since there is no horizontal pressure on the boards as they are loosened from the panel. Drilling also removes a tiny (<0.2mm) bit of the corner, which improves handling by removing sharp corners from the boards. To specify that corner tabs should be drilled, set a check mark by Corners|Drilled.

Note: For purposes of depanelization, the tab width is the width of the narrowest point on the tab.

-

Make corrections, if necessary. If tabs are placed too close to the corners of the boards, then the program may not be able to differentiate between actual tabs and other small gaps between the ends of slots.

If you need to add a tab that was not automatically created, click on the Tab button (so that it is down). Click near the point where the tab begins, and move the mouse pointer near the point where the tab ends. The selection line will automatically snap to the nearest slot segment endpoint. Release the mouse button to create a depanelization segment.

Note: If the panel slot is defined by its outline rather than its centerline, press and hold Ctrl before you click, so that the slot endpoint is located at the center of the arc which defines the end of the slot. To ignore slot endpoints, press Ctrl and Alt.If you need to delete a depanelization line or drill hole, click on the Delete tab button (so that it is down). Draw a selection rectangle around any portion of the object(s) you wish to delete.

-

Add drill holes (optional). Click on the Drill button (so that it is down). Click on any drill hole in the panel to add a drill hole to the milling file. Drill holes are used for registration pins. Registration holes are drilled separately from tab removal slots/holes (either in a separate file, or followed by an M00 compulsory stop).

-

Save the milling file. Click on the Save button to save the milling file. The default file format is G-Code, but the file may also be saved in Gerber format. After specifying a file name, the Milling program setup dialog box is used to specify the necessary parameters to generate an output file with the correct coordinates and operating commands for the target milling machine.

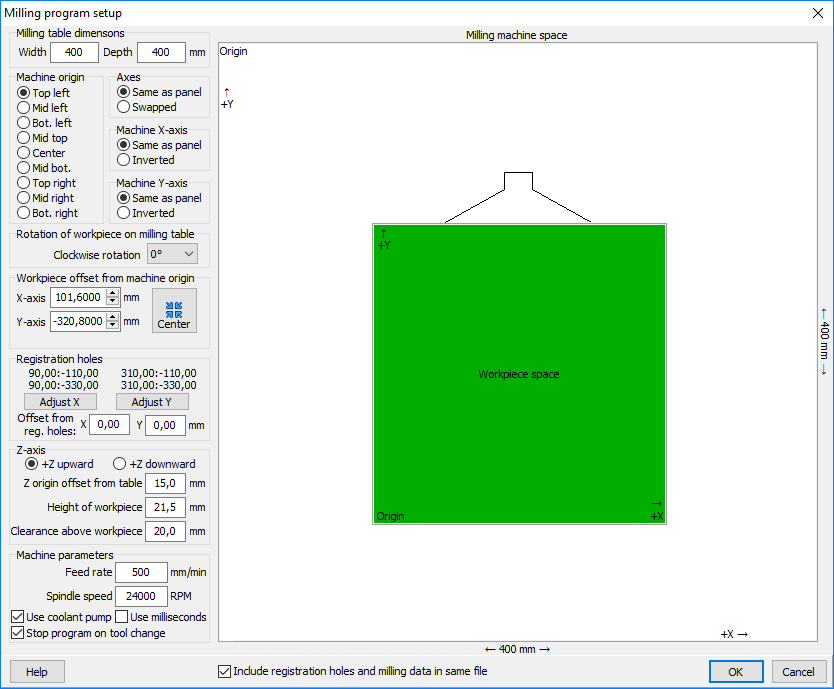

Depanelizer milling program setup

Depanelizer milling program setup BruceThe Milling program setup dialog box specifies the transformation of coordinates from the workpiece coordinate system to the coordinate system of the milling machine. These include machine specific coordinate parameters, placement of the workpiece within the machine space, registration holes (if applicable), z-axis parameters, and additional machine parameters.

Machine specific coordinate parameters

Machine table dimensions: The width and depth of the milling table. These values are used to display the milling space in the dialog box, and to center the workpiece within the milling space.

Machine space origin: The location of the coordinate origin in the machine space. Top is farthest from you when facing the machine.

Axes: Normally, the machine axes will be the same as the (unrotated) workpiece, i.e. X is X and Y is Y, or X is left-right and Y is front-back. If necessary, they may be swapped.

Machine X-axis and Machine Y-axis: Normally, the positive direction of a machine axis is the same as for the workpiece. If necessary, the direction may be inverted.

Placement of the workpiece within the machine space

Rotation of workpiece on milling table: The placement of the workpiece on the table may be rotated, if desired. This rotation is added to any rotation of the workpiece that may have been specified in the designer module.

Workpiece offset from machine origin: This is the offset from the machine space origin to the workpiece origin. This may be adjusted as necessary to place the workpiece at the desired location on the milling table.

The Center button sets the workpiece offset so that the workpiece is centered on the table. This is useful after having made changes to the machine specific coordinate parameters which may have moved the fixture outside of the milling space.

Registration holes

If the workpiece has registration holes (e.g. for a depanelization fixture), then the coordinates of the four registration holes are displayed. If desired, the Adjust X and Adjust Y buttons may be used to adjust the offset so that the coordinates of the registration holes are a multiple of 10.0 mm.

Offset from reg. holes: If (due to manufacturing tolerances) the location of the registration holes in the workpiece is incorrect, it may be desirable to add a small offset to the milling program.

Z-axis parameters

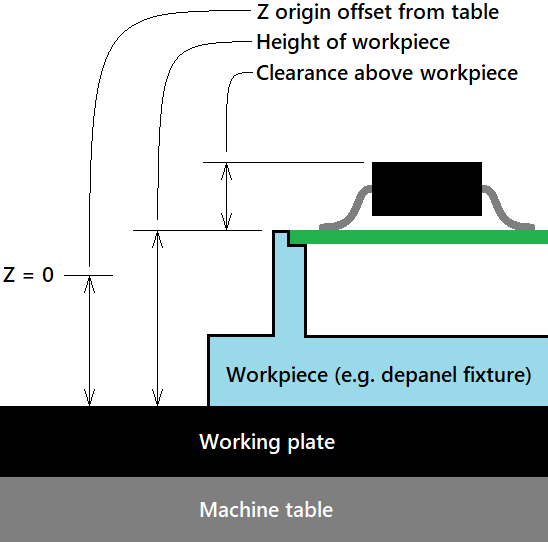

Z-axis: The Z-axis is normally positive in the upward direction. If necessary, this may be inverted.

Z-axis: The Z-axis is normally positive in the upward direction. If necessary, this may be inverted.

Z-origin offset from table: This is the distance from the bottom edge of the workpiece to the Z-axis origin. If the origin is above the workpiece bottom, and +Z is upward, then this will be a positive value. If you make use of a tool homing device to set the Z-axis origin, then this offset should be equal to the thickness of the homing device when it rests on the same surface as the workpiece.

Height of workpiece: This is the distance from the bottom edge of the workpiece to the top of the workpiece. By default, this offset is automatically calculated from the workpiece dimensions. However, it may be adjusted, if necessary.

Clearance above workpiece: This should be slightly larger than the maximum height of any objects extending from the upper surface of the workpiece (e.g. components on the upper side of a panel being depanelized). The cutting tool will retract to 1mm above this height before moving from one cutting point to the next.

Additional machine parameters

Feed rate: The speed at which the cutting tool travels through the material being cut.

Spindle speed: The clockwise rotation speed of the cutting tool. Note: Counterclockwise spindle rotation is not supported.

Use coolant pump: If checked, the program will turn on/off the machine’s coolant pump.

Use milliseconds: If checked, the machine expects the spindle spin-up delay to be specified in milliseconds. Otherwise it is specified in seconds.

Combined or separate files

When generating milling data for multiple output processes (such as for both sides of a solder pallet), the data may be output as a combined file or as two separate files. Use the Include… check box to specify whether one or two output files will be generated.

Machine specific parameters

Upon closing the dialog box, machine specific parameters are saved for re-use the next time a milling program is generated. These include: machine table width, depth and origin, axis swapping and inversion, z-axis inversion, feed rate, spindle speed, coolant, and time in seconds or milliseconds. The option to include/exclude registration holes in the milling file is also saved.

Designing a depanelization fixture

Designing a depanelization fixture BruceA depanelization fixture holds the panel and boards securely in place during the milling process. In addition to the fixture walls (which are automatically calculated), support pedestals and suction cups need to be placed at appropriate locations for each board in the panel.

Select the placement of the dust removal nozzle (for connection to a vacuum cleaner) and the vacuum hose nozzle (for connection to a vacuum pump). Then specify the dust and vacuum nozzle diameters. Note: Changing these parameters will delete all support pedestals and suction cups.

- Suction cups: Each board, each cutout and the panel frame should have one or more suction cups to hold the material in place during routing. These must be located at points where there the suction cup will have complete contact with the lower side of the board. (No via holes, components or component pins.)

For each of the suction cup diameters, an estimated suction force is shown. We recommend a suction of at least 10g per cm² of board area and at least 10g per cm spacing between suction cups (or 20g pr cm from cup to board edge). - Hole support pedestals: These may be placed at any through-hole with a diameter of at least 2.0 mm. There must be at least 1.5 mm clearance around the hole for the shoulder of the pedestal.

- Slot support pedestals: These may be placed at any slot (though we recommend a slot width of at least 2.0 mm). There must be at least 1.5 mm clearance on each side of the slot for the shoulder of the pedestal. Note: If a slot support pedestal is placed on a curved slot or on a slot that is not long enough, then a hole support pedestal will be placed instead.

Note: Around the foot of each support or suction cup pedestal there should be an additional 2 mm clearance for components with a component height within 5 mm of the specified maximum component height.

Each board should have enough support pedestals to remain immovable, both vertically and horizontally, throughout the milling process.

If the panel is a regular array of a single product which has been created by the Macaos Panel Module, then the lower left board in the panel will be highlighted with a yellow rectangle when placing suction cups or hole support pedestals. A suction cup or pedestal placed within this board will automatically be duplicated to all of the other boards.

You should also specify the Component height of components mounted on the underside of the boards. Note: If you specify less than 10 mm as the maximum height of underside components, then a value of 10 mm will be used, in order to allow sufficient height for the suction cup pedestals.

The fixture will be manufactured in white photopolymer plastic. If desired, you may specify that the fixture be coated with Anti-static paint.

Use the Publish button to upload the fixture to the Macaos Repository. Initially, the fixture may only be viewed as a 2D schematic drawing. Once an order has been placed for the fixture, a Macaos engineer will generate a 3D model of the fixture, which may then be viewed in the product browser.