Milling details

Milling details Bruce The pallet is milled from a sheet of “synthetic stone,” a machinable composite material. Pockets and engraving on the top side as well as chamfers and pressure relief on the bottom side mean that both sides of the sheet must be milled. Macaos generates a milling file which does the following:

The pallet is milled from a sheet of “synthetic stone,” a machinable composite material. Pockets and engraving on the top side as well as chamfers and pressure relief on the bottom side mean that both sides of the sheet must be milled. Macaos generates a milling file which does the following:

-

Drill mounting holes for stiffeners/solder dams. These holes also serve as registration holes. Holes are drilled 8 mm into the working plate beneath the pallet sheet.

-

Stop to insert registration pins in the holes. Remove edge clamping from the sheet.

-

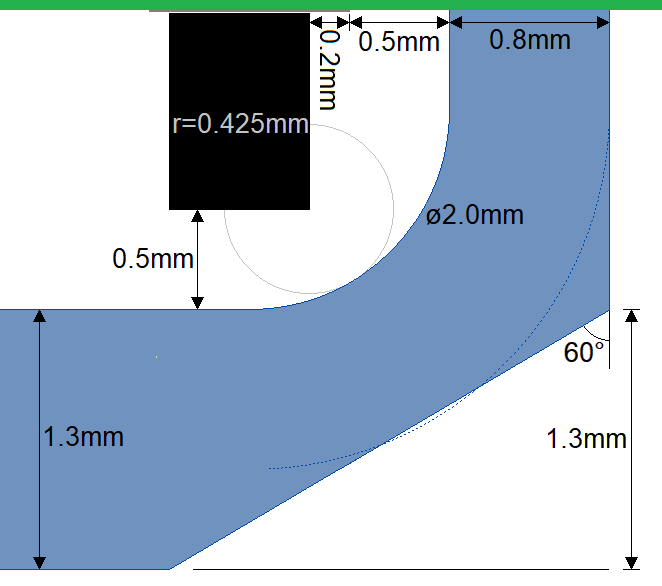

Mill the pallet edges, engraving, board pocket, component pockets and pallet openings. Component pockets are first cleared (roughed) with a flat-bottom end mill, after which a ball nose end mill is used to finish the pocket’s rounded edges.

-

Stop to flip the sheet left/right (around the y-axis, so that +x becomes -x). Use the same registration holes and pins.

-

Mill pressure relief areas (if any) and chamfer the leading/trailing pallet edges and the edges of pallet openings.

This requires several different types of carbide or diamond cutting tools, as shown in the following table:

-

Purpose

Style

Diameter (mm)

Stiffener/alignment holes

Drill/mill

3.0

Openings in pallet

Drill/mill

2.5

Engraved text and symbols

Drill/mill

1.0, 2.5

Board pocket edges

Flat bottom

2.5

Pocket floors and rail fingers

Flat bottom

6.0

Component pocket edges

Ball nose

2.0

Bottom side chamfered edges

120° chamfer cut

6.0

The 3.0 mm tool should have a length of cut (LOC) at least 10 mm longer than the sheet thickness. All other tools should have a length of cut (LOC) at least 2 mm longer than the sheet thickness.