Macaos Enterprise 3.4 (December 2010)

Macaos Enterprise 3.4 (December 2010) Bruce

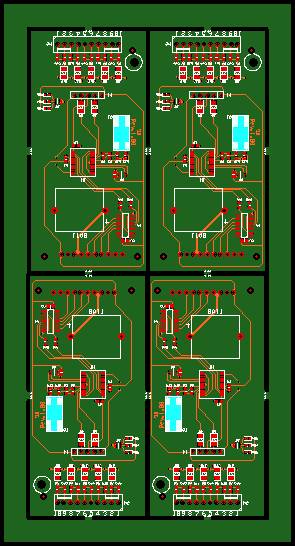

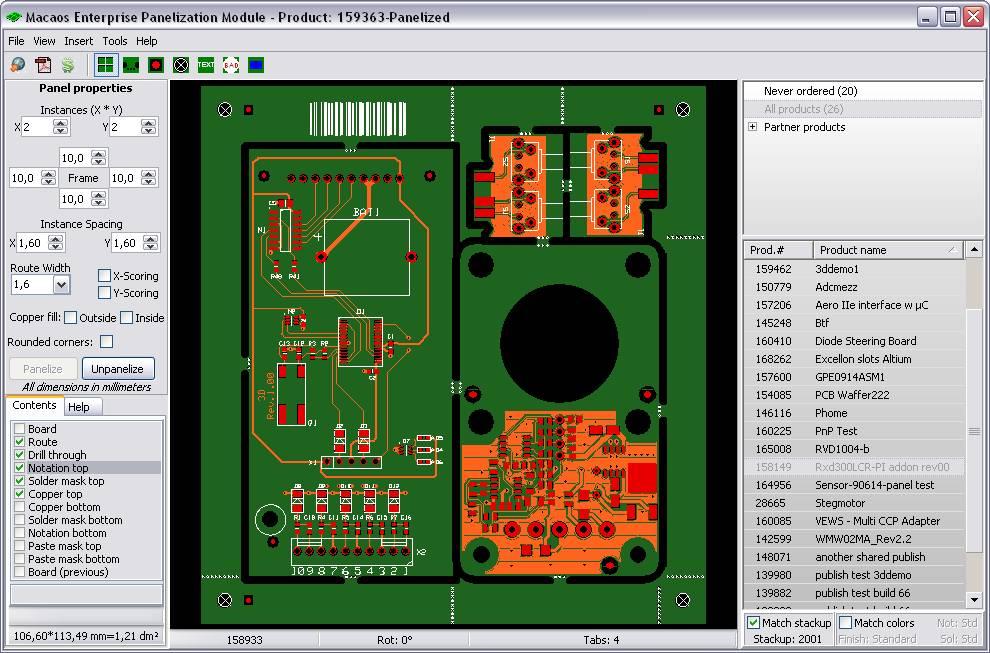

Panelization module improvementsMulti-product panels

Select a board in the product browser and open the panelization module. Press Ctrl+R to open the product chooser, which lists all board products that match the stackup (or number of layers) and finish/colors (if selected) of the first product. Drag a product from the product list into the panel to add the board to the panel. Move the board to the desired location and click to place the board. All boards should be placed on the panel before adding tabs, fiducials, drill holes, etc. If no tabs are added to the panel, then the boards will be delivered as individual boards. Move and rotate boards within a panelAny board in a panel may be moved or rotated as desired. Draw a selection rectangle over part of a board's contour to select the board. The board will move with the mouse, but will automatically snap to align with the edges of neighboring boards. Press Ctrl to disable snap. Press the space bar to rotate 90 degrees. Click to place the board into the panel. Add assembly masks to a panel |

Import module improvements |

Fiducial marks at specified coordinates.Fiducials may be added to a board at specified coordinates by pressing Ctrl+Alt and then clicking on the board. |

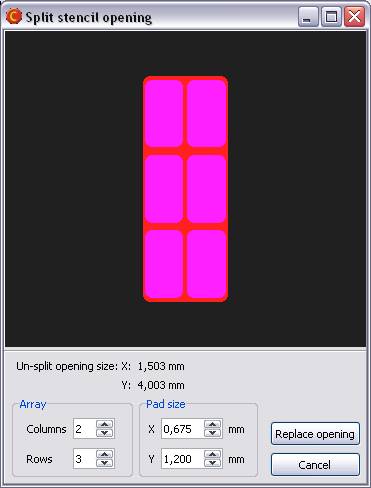

Stencil module improvements |

Product browser improvementsAdd assembly masks to existing productsAvailable only with pro license Add data for peel-off mask (blue mask), paste mask, glue mask, carbon or hard gold to an existing product by selecting the product and clicking the Add masks button. Assembly mask data is added in the same manner as for panels (described above). |

Standard foldersFour new standard folders have been added to the product browser.

|

Product searchIt is now possible to choose between "begins with", "ends with", "equals" and "contains" when searching for a product. |

Product historyA new progress indicator shows the status of active orders. |

In many cases, it may be desirable to put several different boards together into a panel. For example, by putting the different boards in a system together into a panel, it would be possible to order one panel per system. Often, the price of a multi-product panel will be substantially lower than the price of the same quantity of boards ordered individually.

In many cases, it may be desirable to put several different boards together into a panel. For example, by putting the different boards in a system together into a panel, it would be possible to order one panel per system. Often, the price of a multi-product panel will be substantially lower than the price of the same quantity of boards ordered individually.